By Robin Anderson

Wildfires are an essential part of forest and rangeland health. However, as the U.S Geological Survey (USGS) points out, they are becoming more intense and destructive following the trend toward hotter and drier climate conditions.[i] For homeowners and building industry pros, the growing danger of fires has made ignition resistant construction through high-performance, resilient building materials exponentially more important. And, when enhancing a home’s resistance to fire, the roof must specifically be addressed as it is a common ignition point for flying embers.

As a fire burns, embers are emitted and are pushed by the winds generated by the fire. The type of fire determines the amount of embers produced, as well as the distance those embers travel. Embers can carry enough heat energy to ignite combustible structures and ignition can occur when they blow against, or land upon, the surfaces of a home. Science supporting the critical need for ignition-resistant construction specifically features Class-A roofing (among screened attic vents and composite decking) as a significant defense against ember-initiated ignition of homes and structures.[iii]

Class-A rated roofs encompass the covering material and the overall assembly and are tested by a third-party lab which subjects the roofing assembly to a fire brand test, ASTM E-108 Burning Brand, among other tests. To be deemed Class-A, the fire cannot penetrate the roof or cause the structure to ignite before the brand is consumed and burns out during the test period.[iii]

Class A Fire Testing

Unified Steel™ Stone Coated Roofing materials can resist very high temperatures and are proven to provide ignition resistance. A lightweight roofing material, at 1.5 pounds per square foot, stone-coated steel benefits from the structural strength of steel and is used in both new construction and in roofing retrofits. The high-quality steel is treated with primers to enhance the adhesion of the acrylic polymer base coat that is used to bond stone granules to the steel. The resulting roof system helps withstand the test of time no matter the climate or condition.

For product warranty details, please see Unified Steel™ Product Warranty The warranty found there is the sole warranty applicable to Unified Steel™ Stone Coated Roofing products.

Building Codes & Assembly Considerations

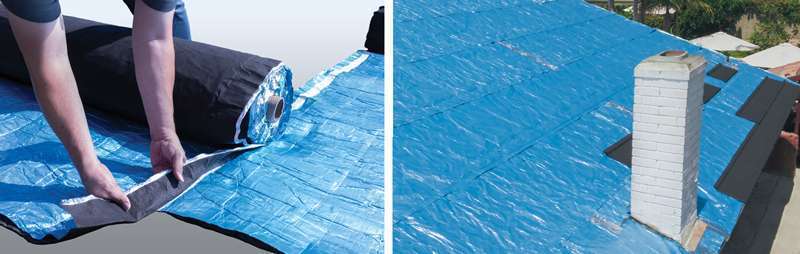

State-by-state building codes address Class-A roofing. For example, current building code in California[iv], a state known for severe wildfire risk, mandates the roof assembly is installed in accordance with its listing and the manufacturer’s installation instructions to be ignition resistant. For Unified Steel™, this requires the roof assembly include a specific underlayment such as Sol-R-Skin™ BLUE.

Sol-R-Skin BLUE Underlayment

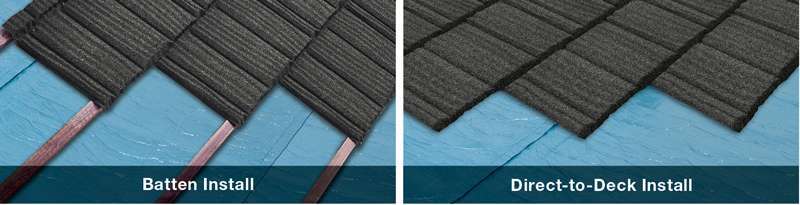

Westlake Royal Roofing Solutions’ guidelines approve Unified Steel™ panels to be installed either on a batten or direct-to-deck (the latter is commonly used when the existing sub-deck is solid or spaced sheathed, eliminating the batten needing to act as the panel support). Today’s panel designs also allow for exposed or hidden fastening systems.

Roof gutters are also addressed in California’s code. The code states they must be provided with the means to prevent accumulation of leaves and debris. Stone coated steel roofs can use gutter guards in a fine mesh to allow water into the gutter but prevent leaves and debris from entering.

California’s building code also advises on roof coverings, stating where the roof profile allows a space between the roof covering and roof decking, the spaces shall be constructed to prevent the intrusion of flames and embers, be fire-stopped with approved materials like Sol-R-Skin BLUE, or have one layer of minimum 72-pound mineral surfaced non-perforated cap sheet complying with ASTM D3909 installed over the combustible decking.

California code also includes roof valley treatments. When installed per Unified Steel’s guidelines, utilizing proper underlayment and the 26-gauge corrosion-resistant steel valley metal, the system can meet the requirements set by the state.

“The importance of an ignition-resistant roof material and assembly cannot be overstated, especially in fire-prone regions” says Mark McMillan, sales manager with Horn Brothers Roofing, a Colorado-based roofing contractor. “Stone coated steel roofing has been growing in popularity amongst our customers because of its ability to protect homes from ignition caused by flying embers.”

[i] U.S. Geological Survey, Wildfire and Climate Change.

[ii] U.S. Environmental Protection Agency, Climate Change Indicators: Wildfires.

[iii] FireSafe Montana, Ignition Resistant Construction Guide: A Guide to Smart Construction and Wildfire Mitigation in the Wildland Urban Interface.

[iv] California Building Code, Chapter 7A: Materials and Construction Methods for Exterior Wildfire Expo

Robin Anderson is Technical and Strategy Development Manager with Westlake Royal Roofing Solutions, the leader in efficient and durable roofing systems and components. Contact Robin at randerson3@westlake.com, visit www.westlakeroyalroofing.com.